In today’s fast-paced manufacturing landscape, businesses are constantly seeking innovative solutions to enhance efficiency and reduce production costs. One such advancement that has captured the attention of engineers and manufacturers alike is CNC milling.

This sophisticated technology not only promises precision but also offers a plethora of design possibilities that were previously unimaginable. But as with any investment, the question arises: are CNC milling parts truly worth the financial commitment? Delving into this query reveals a complex interplay of factors, from cost-effectiveness to product quality, and opens up a fascinating discussion about the long-term benefits that can position your business at the forefront of the industry.

As we explore the multifaceted advantages of CNC milling, well uncover the reasons why this investment might just be the key to unlocking your company’s potential.

Benefits of CNC Milling: Why Businesses Choose This Technology

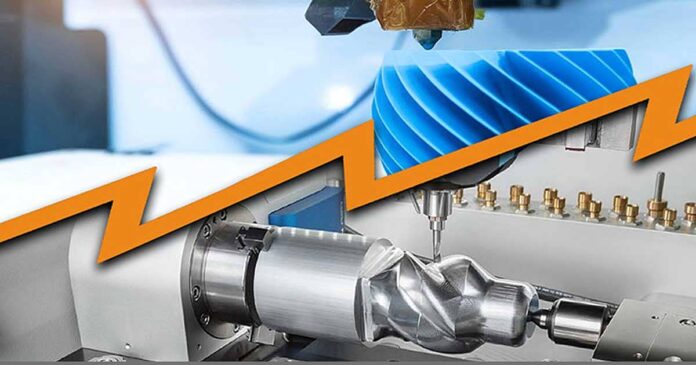

CNC milling technology has revolutionized the manufacturing landscape, offering a myriad of benefits that compel businesses to embrace it wholeheartedly. Precision is paramount, and with CNC milling, companies can produce intricate components with an accuracy that manual methods simply cant match.

This technological prowess not only ensures that parts fit seamlessly in assembly but also reduces material waste, enhancing cost-effectiveness in the long run. Moreover, the speed at which CNC milling operates allows for rapid prototyping, enabling businesses to accelerate their time-to-market without compromising quality.

Scalability is another significant advantage; whether producing a single prototype or thousands of identical parts, CNC machines maintain consistent output and efficiency. In an era where innovation and adaptability are crucial, investing in CNC milling equips businesses with the tools needed to stay competitive and responsive to market demands.

Cost Analysis: The Financial Implications of CNC Milling

When delving into the financial landscape of CNC milling, it’s essential to weigh not just the immediate costs but also the long-term savings and value it can bring to your business. Initial investments in CNC machinery and software can be significant—ranging from thousands to tens of thousands of dollars.

However, these upfront costs are often offset by the precision and efficiency CNC milling offers. Consider the reduction in labor costs due to automation; skilled operators are essential, but the necessity for extensive manual intervention diminishes dramatically.

Furthermore, the ability to produce complex parts with minimal waste can lead to substantial savings over time, as raw material expenses are reduced. It’s not just about crunching numbers; its about the return on investment over years, the enhancement of product quality, and the agility to meet a fluctuating market demand.

Ultimately, while the initial price tag may give some pause, the financial benefits that stem from using CNC milling often prove to be worth every penny.

Customization and Flexibility: Tailoring Parts to Your Needs

Customization and flexibility stand as paramount advantages when considering CNC milling parts for your business. Imagine creating components that fit your exact specifications, an opportunity unattainable with off-the-shelf products.

CNC machining allows for intricate designs and precise tolerances, tailoring the parts to meet unique operational demands. Need a specific material that withstands high temperatures or a shape that integrates seamlessly with existing systems? CNC milling can accommodate those needs, making it possible to craft everything from specialized automotive parts to bespoke medical devices.

This level of personalization not only elevates the performance of your products but also enables swift adjustments during the production process, ensuring that your operations remain efficient and responsive to market changes. The ability to adapt and innovate continuously makes investing in CNC milling parts a strategic move, amplifying your products relevance in a competitive landscape.

Conclusion

In conclusion, investing in CNC milling parts can significantly enhance your businesss production efficiency, precision, and overall quality of output. By streamlining manufacturing processes and reducing waste, CNC milling not only elevates your product standards but also contributes to long-term cost savings.

As industries continue to embrace advanced technology, businesses that prioritize CNC milling will likely gain a competitive edge. Ultimately, the decision to invest in CNC milling parts should be viewed not just as an expense, but as a strategic move towards innovation and growth in an ever-evolving marketplace.